Pre Engineered Building System

Facilities

Our dedicated and well trained technicians monitor our process at every stage including raw material selection from leading steel companies and Quality check at every stage of production to ensure our finished supplies are confirming as per industry standards.

We have the installed capacity of around 5,000 MT steel per year to produce Primary Structural Members. The plant is fully equipped with state-of-the-art latest machinery such as High-end CNC Plasma Profile Cutting Machine with Hyper therm Power source, H -Beam Automatic Welding line with Lincoln Electric SAW, MIG Welding , Drilling , Punching machines etc.,

Products:

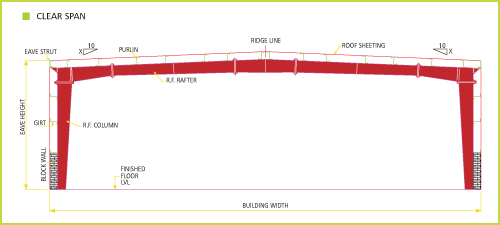

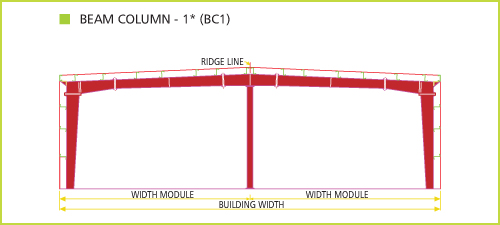

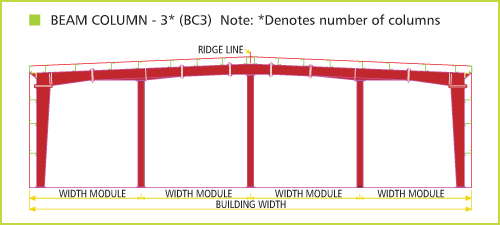

Pre Engineered Buildings from design to completion.

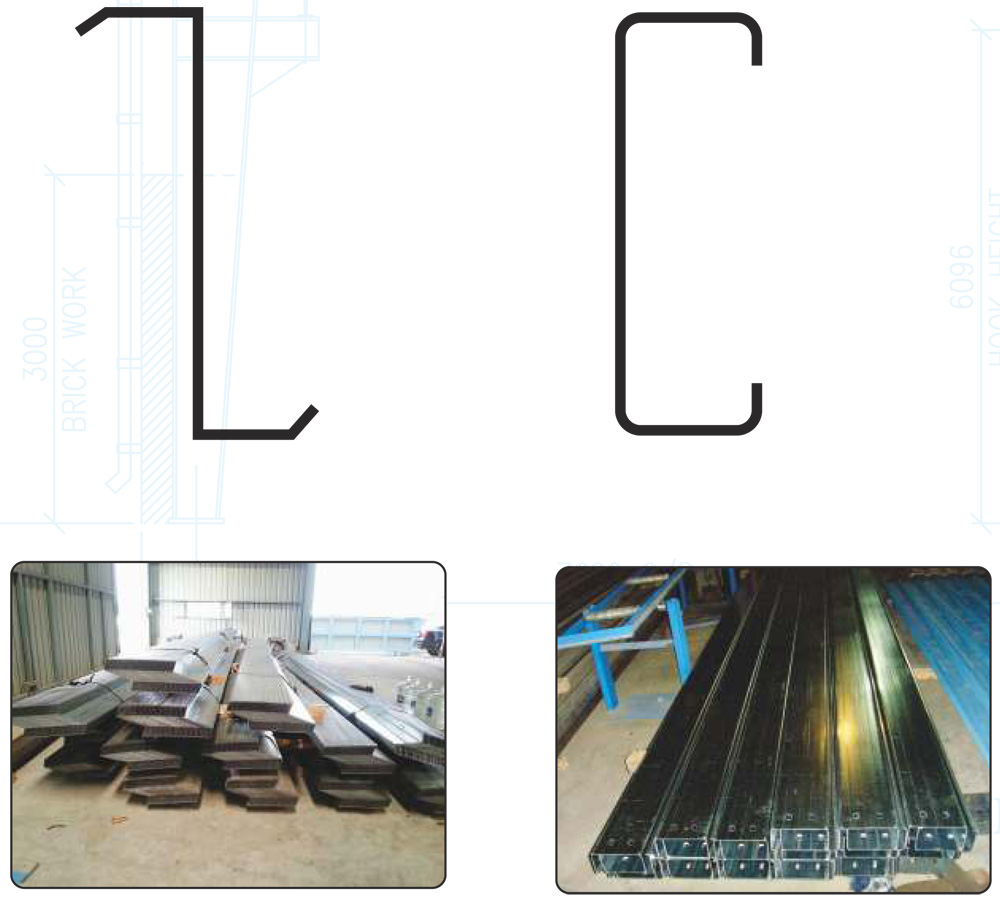

Primary Members

Advantages

- Durable and Economical

- Flexible and Time saving

- Architectural versatility

- Earthquake Resistant

Applications

- Industrial Sheds

- Commercial Buildings

- Sports Facilities

- Aircraft Hangers

- Warehouses and Storage

- Metro and Bus Terminals

Secondary Members

Cold Roll Formed C And Z Sections With Online Pre Punching

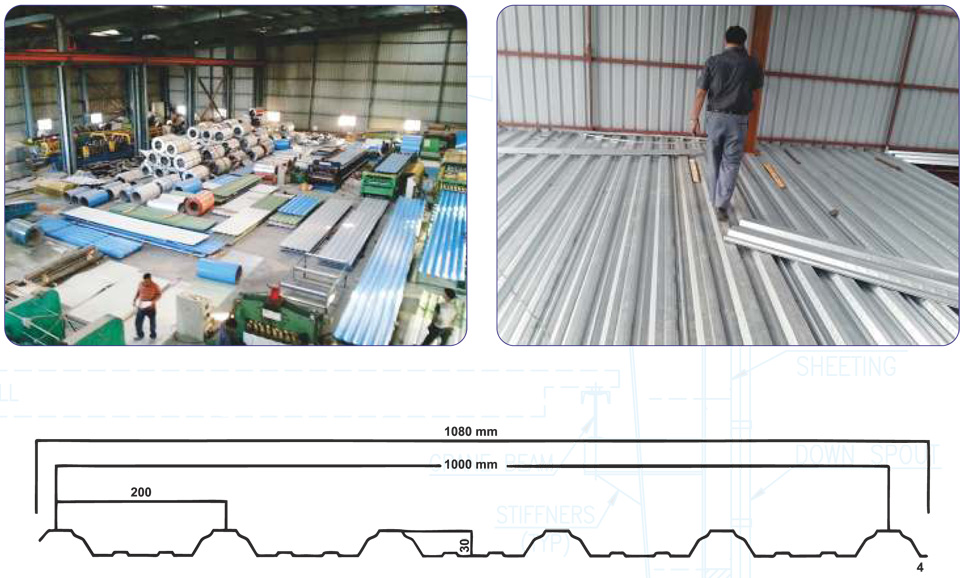

Roofing & Cladding Sheets

Cold Roll Formed C And Z Sections With Online Pre Punching

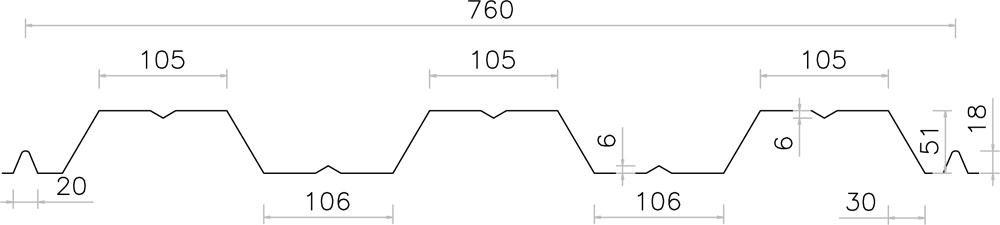

Deck Sheets

Steel decking profile is used as composite floor system or permanent from work. It binds with concrete slab and together forms a part of the floor structure.

Advantages

- Light weight- Reduces concrete floor weight by almost 50%.

- Multi use - For mezzanines, walkways, platforms etc.,

- Time saving - Easy installation

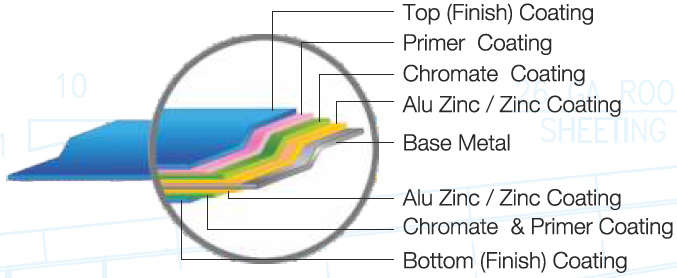

Structure of Pre-Painted Steel Sheet